- Tel : +86-0311-85236281

- E-mail : sales@wirecloths.com

1、 Advantages of Polyester Mesh

1. High strength: Polyester mesh has high strength and can withstand large weights and pressures, making it suitable for the manufacturing of various heavy-duty buildings and mechanical equipment.

2. Corrosion resistance: Polyester mesh has good corrosion resistance and can resist the erosion of chemicals such as acid, alkali, salt, etc., making it suitable for use in various harsh environments.

3. Wear resistance: Polyester mesh has good wear resistance and can resist friction and wear, making it suitable for various occasions that require wear resistance.

Polyester mesh is a type of mesh fabric made from polyester materials, which has various advantages and wide applications. The following is a detailed introduction to polyester mesh

1、 Advantages of Polyester Mesh

1. High strength: Polyester mesh has high strength and can withstand large weights and pressures, making it suitable for the manufacturing of various heavy-duty buildings and mechanical equipment.

2. Corrosion resistance: Polyester mesh has good corrosion resistance and can resist the erosion of chemicals such as acid, alkali, salt, etc., making it suitable for use in various harsh environments.

3. Wear resistance: Polyester mesh has good wear resistance and can resist friction and wear, making it suitable for various occasions that require wear resistance.

4. High temperature resistance: Polyester mesh has good high temperature resistance and can maintain stability and strength in high temperature environments.

5. Long lifespan: Polyester mesh has a long service life and can maintain its performance and appearance for a long time.

2、 Application of Polyester Mesh

1. Construction field: Polyester mesh can be used to manufacture various building components and materials, such as bridges, tunnels, highways, etc.

2. Mechanical manufacturing: Polyester mesh can be used to manufacture various mechanical components and structural parts, such as automobiles, airplanes, ships, etc.

3. Petrochemical industry: Polyester mesh can be used to manufacture various petrochemical equipment, such as reaction vessels, heat exchangers, etc.

4. Food processing: Polyester mesh can be used to manufacture various food processing equipment, such as baking equipment, meat processing equipment, etc.

5. Other fields: Polyester mesh can also be used to manufacture products in various other fields, such as textile machinery, papermaking machinery, etc.

3、 Classification of Polyester Mesh

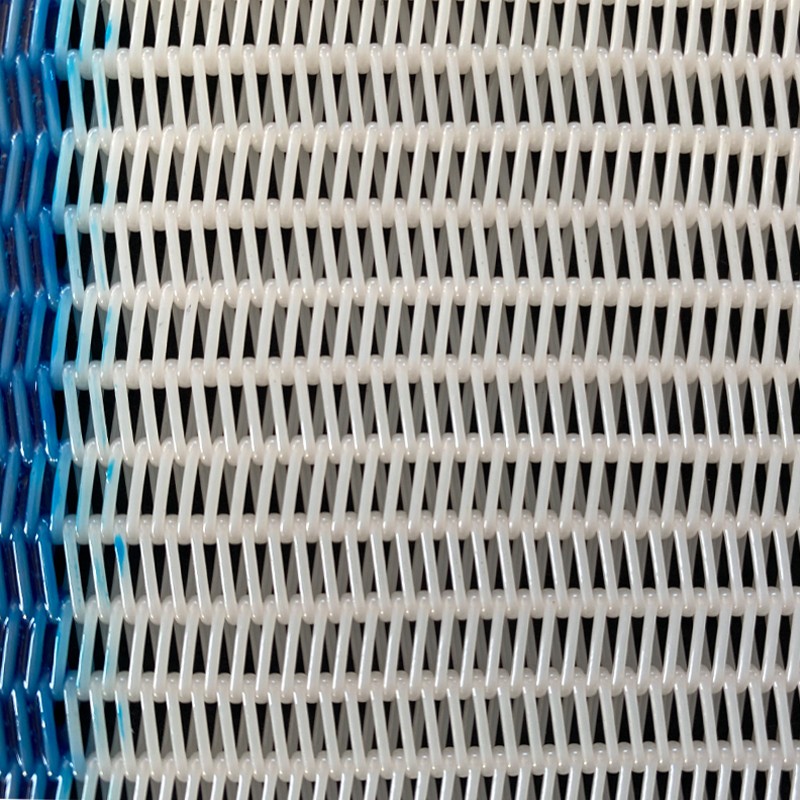

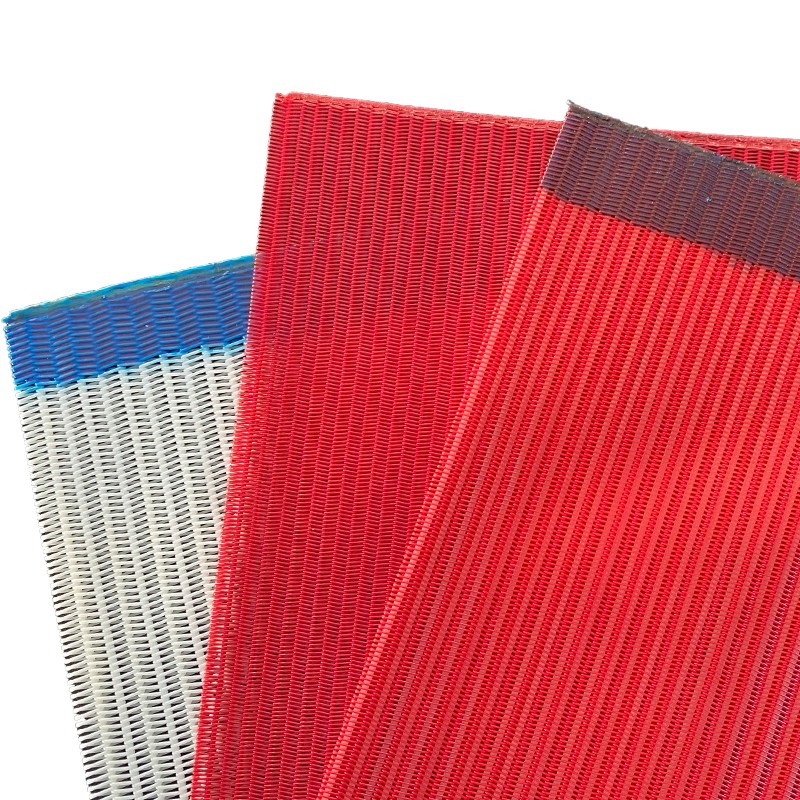

According to different weaving methods and usage scenarios, polyester mesh can be divided into various types, such as non-woven mesh belt, polyester spiral mesh, square hole flat woven mesh, herringbone sludge dewatering mesh, spiral filter press mesh, papermaking forming mesh, anti-static grid, desulfurization mesh, etc.

4、 The production process of polyester mesh

The production process of polyester mesh includes multiple steps such as weaving, dyeing, and heat treatment. Among them, weaving is a key step in the production of polyester mesh, which involves selecting appropriate raw materials, weaving methods, and weaving equipment. Dyeing is to give polyester mesh a specific color and appearance effect. Heat treatment is to improve the strength and stability of polyester mesh.

Copyright © HEBEI REKING WIRE MESH CO.,LTD. All Rights Reserved

Technical Support: